CORRECTIVE MAINTENANCE

This is maintenance carried out after a failure has occurred, intended to put an item back in condition to perform a required function. Stopped machines or damaged equipment cause great harm to any company, generating several production line problems and unwanted delays, often caused by small errors.

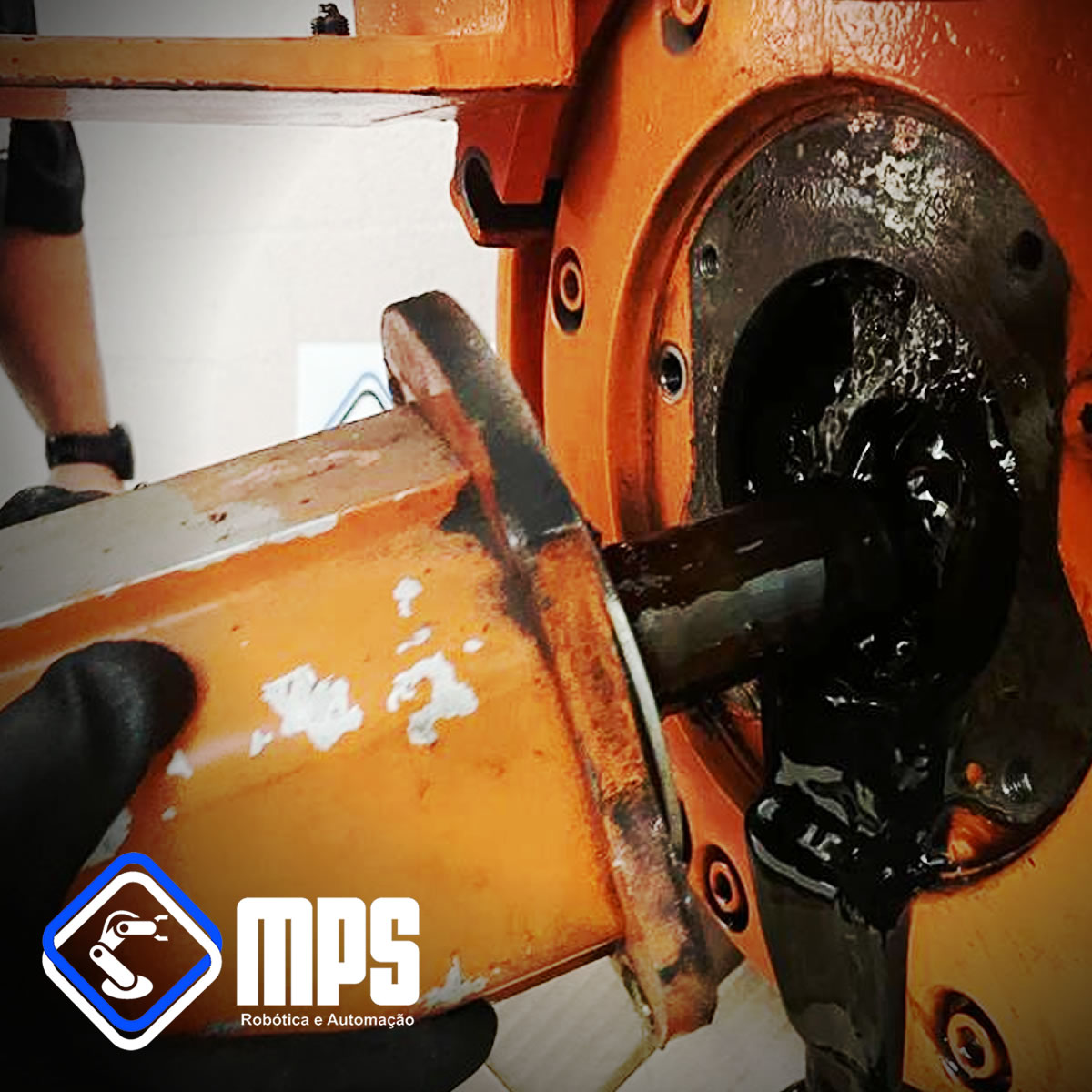

PREVENTIVE MAINTENANCE

Performed at predetermined intervals, or according to prescribed criteria, intended to reduce the probability of failure or degradation of the functioning of an item. Robots with a very high level of external residue tend to present failures, creating difficulty at the time of repair and especially in the robot movement axes. On a scheduled basis, we offer a service where we seek to anticipate a possible failure with the customer, reducing machine downtime and increasing equipment and production reliability.

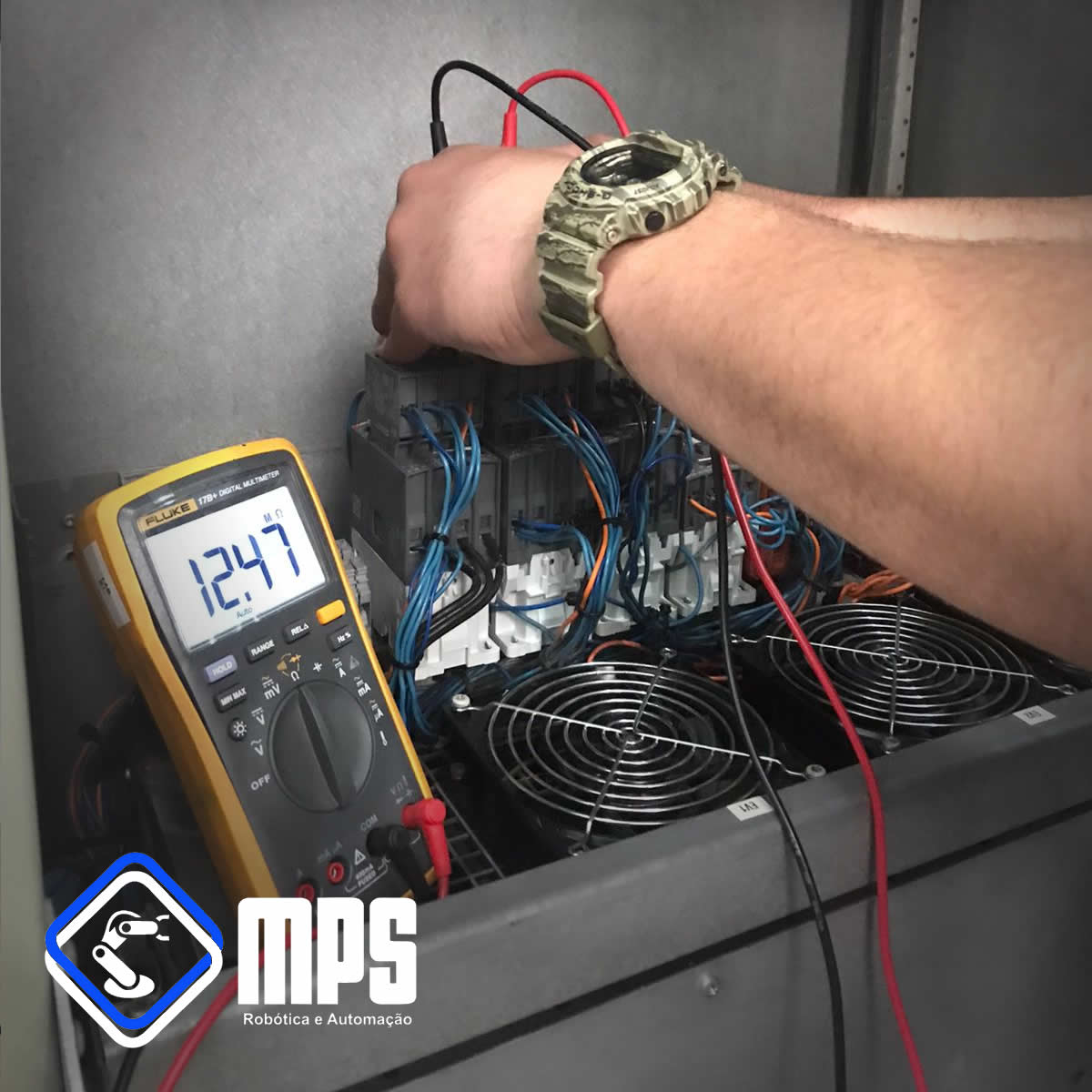

PREDICTIVE MAINTENANCE

This type of maintenance is carried out by the continuous monitoring of an equipment or system and the attempt to define its future state through the data collected over time. making them provide greater efficiency for longer.

ROBOTS RENOVATION

For the most critical cases, in which a deeper intervention is necessary to restore the functionality of the equipment, MPS Robotica e Automação also offers a robot refurbishment service, which consists of a complete evaluation of the robot's electro-electronic and mechanical components, performing the replacement of damaged items, due revision of the boards, ending with load tests, ensuring the characteristics and original capacities of the factory.

MAINTENANCE CONTRACTS

Understanding the importance and need for recurring maintenance, and seeking to offer a quality service that provides peace of mind to our customers, MPS Robotica e Automação also provides maintenance contracts with 24-hour support through our service channels, delivering what is best in the segment.