Painting Robots: The Revolution in Industry and its Benefits

In the era of industrial automation, robots play a crucial role in optimizing processes and improving efficiency in various areas of production. One sector that has experienced significant transformation is industrial painting, where painting robots have emerged as an innovative and effective solution. Let's explore how these robots are revolutionizing the industry, as well as discussing the benefits in terms of increased productivity and process safety.

The Role of Painting Robots in Industry:

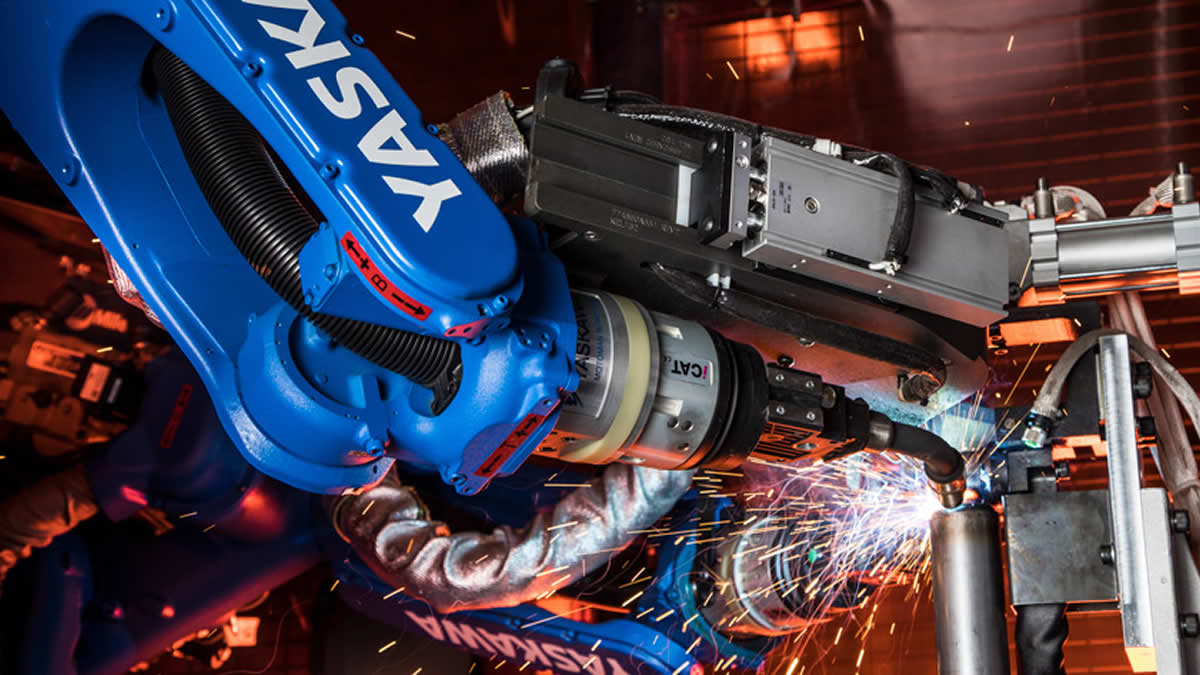

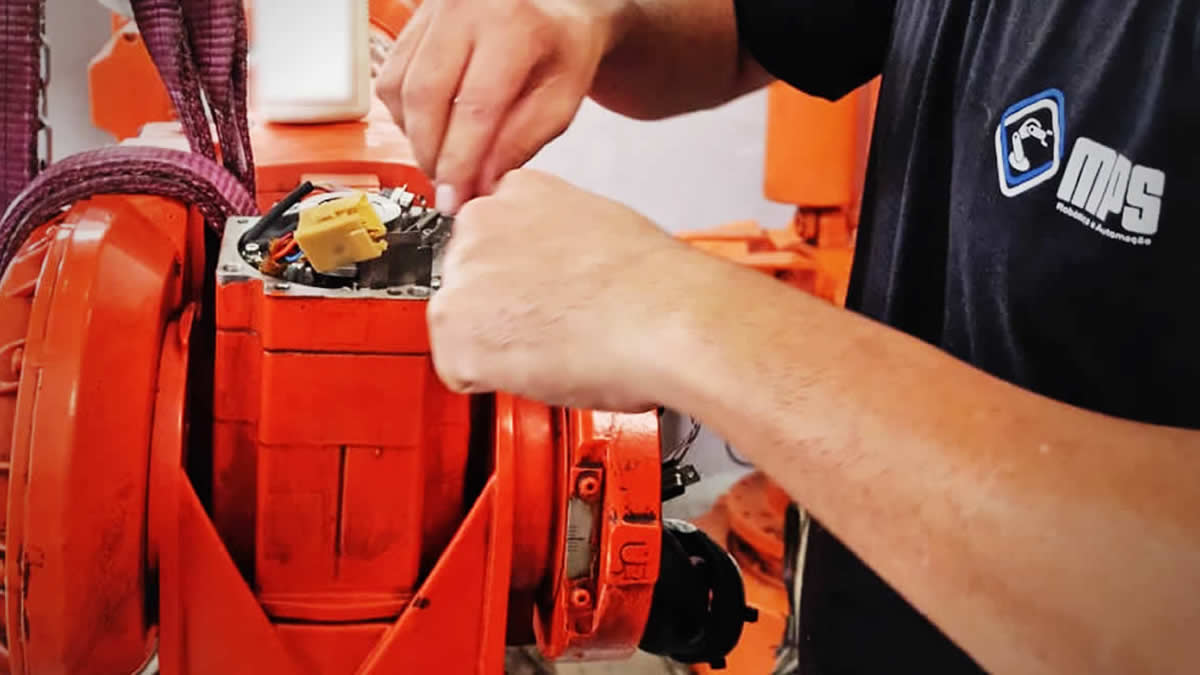

Painting robots are automated devices designed to apply coatings to parts, products, and surfaces accurately and uniformly. They are programmed to follow specific movement patterns, ensuring consistent and uniform coverage across the area to be painted. This eliminates the need for direct human intervention in the painting process, reducing errors and increasing efficiency.

Benefits of Using Painting Robots:

-

Increased Productivity: Painting robots can work continuously without the need for breaks, resulting in faster production cycles and higher output. Additionally, their precision and speed in applying coatings ensure more efficient production compared to manual methods.

-

Consistent Quality: The precise programming of painting robots ensures uniform application of the coating on all parts, eliminating variations in quality that can occur with manual painting. This results in high-quality finished products and greater customer satisfaction.

-

Waste Reduction: Painting robots can accurately control the amount of paint applied, minimizing material waste. This not only reduces production costs but also has a positive impact on the environment by reducing the amount of waste generated during the painting process.

-

Enhanced Safety: By replacing manual labor with automation, painting robots significantly reduce the risk of accidents related to exposure to chemicals and toxic fumes. This creates a safer working environment for employees while improving compliance with occupational safety and health regulations.

Curiosities about Painting Robots:

-

Millimeter Precision: Painting robots can operate with impressive precision, allowing for the application of coatings in hard-to-reach areas or on complex surfaces with extreme accuracy.

-

Versatility: These robots can be programmed to handle a variety of materials and types of coatings, from conventional paints to special coatings such as varnishes and epoxies.

-

Integration with Advanced Control Systems: Painting robots can be integrated with advanced control systems, allowing real-time monitoring and adjustment of painting parameters, ensuring consistent and high-quality results.

-

Space Savings: Painting robots take up less space compared to conventional production lines, allowing for better use of factory space and a more efficient production layout.