Importance of Preventive Maintenance for Industrial Robots

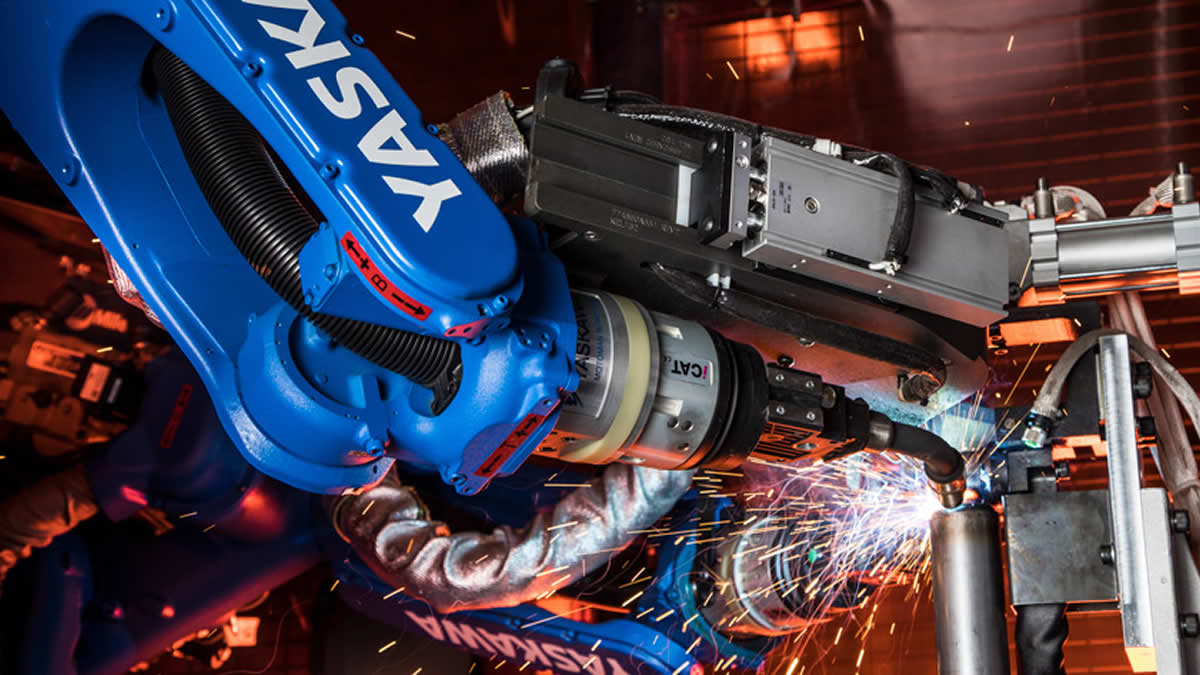

Hello, folks! Today, let's talk about a highly relevant topic in the world of industrial automation: preventive maintenance for robots. Industrial robots play a crucial role in optimizing production processes, increasing efficiency, and boosting productivity in companies. Therefore, it is essential to ensure that these machines are always operating at their maximum capacity. And that's where preventive maintenance comes in.

Preventive maintenance involves a series of scheduled and periodic activities performed on industrial robots with the aim of preventing failures and maximizing their performance. Instead of waiting for a problem to occur and disrupt production, preventive maintenance takes a proactive approach by identifying potential issues before they manifest.

Let's explore some of the key benefits of preventive maintenance for industrial robots:

1️⃣ Cost reduction: By conducting regular inspections on robots, it is possible to identify and correct problems before they become more severe. This helps avoid the need for complex and expensive repairs while minimizing production downtime.

2️⃣ Increased lifespan of robots: Preventive maintenance helps extend the lifespan of industrial robots. With proper care routines, parts experience less wear and tear, allowing the machine to maintain its performance over time.

3️⃣ Enhanced operational availability: Through preventive maintenance, unplanned failures can be significantly reduced, leading to increased operational availability for robots. With less downtime, production remains in full swing.

4️⃣ Improved safety: Industrial robots are designed to operate in complex and often hazardous work environments. Preventive maintenance helps identify and address potential safety issues, ensuring a safer workplace for operators.

5️⃣ Performance optimization: With preventive maintenance, robots can be regularly adjusted and calibrated, ensuring their peak performance. This contributes to product quality and process efficiency.

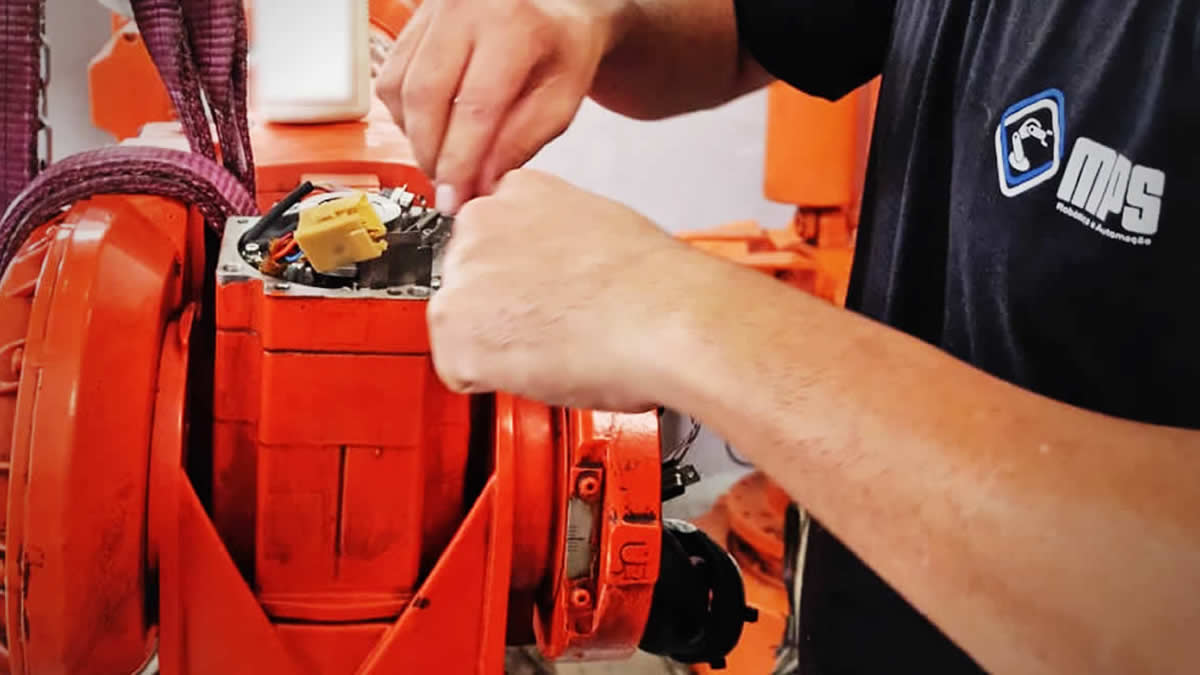

Now that we understand the benefits of preventive maintenance, it is important to emphasize that it should be carried out by qualified professionals following the manufacturer's recommendations. Additionally, having a well-structured maintenance plan with defined inspection intervals, detailed records, and the use of appropriate tools is crucial.

Therefore, if you have industrial robots in your company, remember the importance of investing in preventive maintenance. This practice will allow you to enjoy all the mentioned benefits, ensuring continuous, efficient, and safe operation of your robots.

Did you find our post on preventive maintenance for industrial robots helpful? Share it with your friends and colleagues working in industrial automation. 🚀💪

#IndustrialAutomation #IndustrialRobots #PreventiveMaintenance #Efficiency #Productivity