Robots and Arc Welding: The Perfect Combination for the Industry!

Today, let's delve into one of the most incredible partnerships in the industrial world: robots and arc welding! This innovative combination has revolutionized the industry, bringing greater efficiency, precision, and safety to manufacturing processes. So, buckle up and join us to discover this perfect marriage of technology and the art of welding!

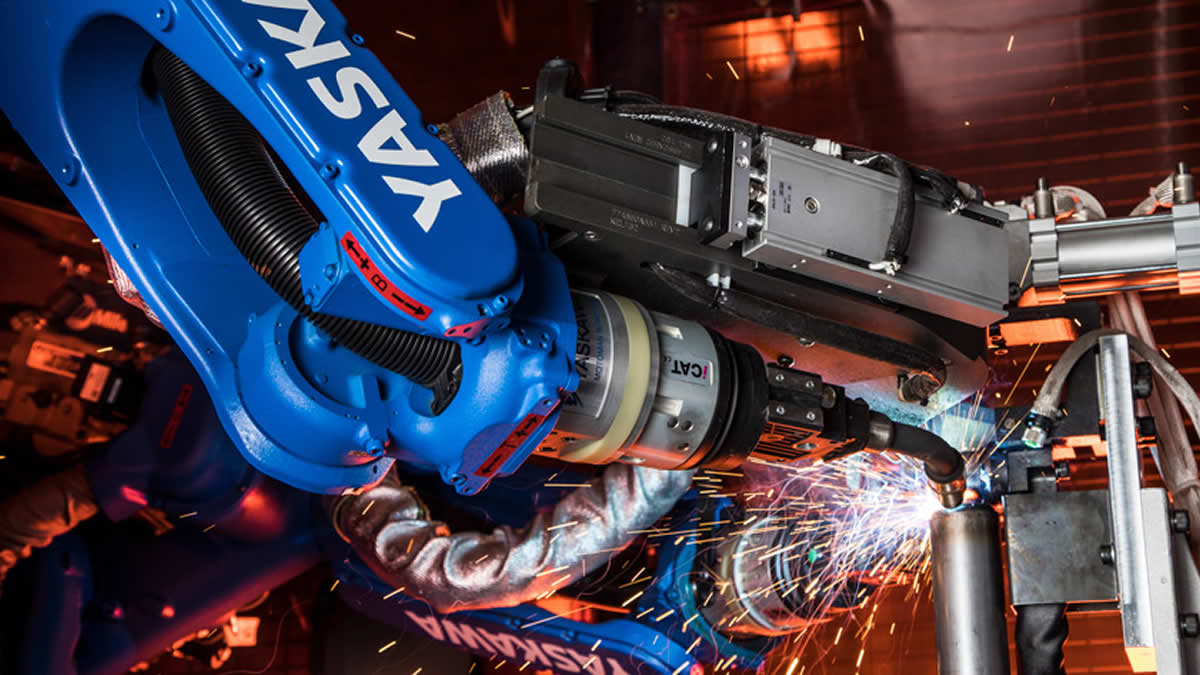

🔧 The power of robots in arc welding:

Robots, with their programmable capabilities and millimeter precision, have become key players in the modern industry. When applied to arc welding, they take on a leading role in automating complex tasks, eliminating the need for direct human intervention in many welding processes.

🎯 Surgical precision:

Arc welding, especially processes like pulsed arc welding and submerged arc welding, requires high precision to achieve consistent and high-quality results. Robots, equipped with advanced vision systems and intelligent algorithms, can detect the nuances of the workpiece and adjust the welding torch's position with surgical precision, ensuring uniform and durable welds.

⚙️ Elevated efficiency:

Integrating robots into production lines allows for a continuous and rapid flow of parts for welding. Robots can work tirelessly, 24 hours a day, seven days a week, significantly increasing productivity and reducing manufacturing cycle times. Moreover, robots' repeatability prevents rework and waste, generating resource savings for companies.

🛡️ Safety first:

Arc welding involves high temperatures and accident risks if not performed properly. By utilizing robots to perform this task, operator safety is enhanced as they can operate the machines from a safe distance, outside the hazard zone. This drastically reduces exposure to fumes and sparks, contributing to a safer and healthier working environment.

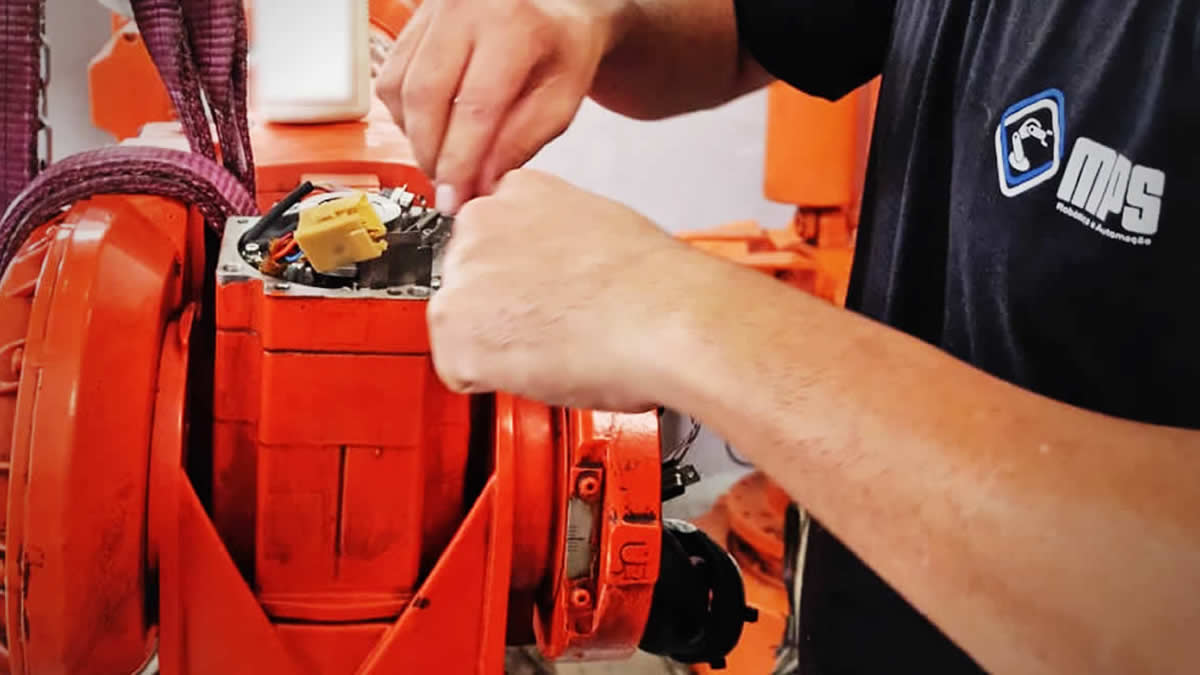

🌐 Robots and connectivity:

Connectivity and Industry 4.0 have come to further amplify the use of robots in arc welding. With the adoption of remote management and monitoring systems, it's possible to control and optimize welding operations in real time, detect faults or deviations, and take corrective actions swiftly.

🚀 The future of arc welding with robots:

With ongoing advancements in artificial intelligence, machine learning, and computer vision, we can expect even more enhancements in integrating robots into arc welding. Precision will be further heightened, productivity rates will increase, and new welding processes can be developed to tackle increasingly complex materials.

Therefore, it's evident that the union of robots and arc welding is an ongoing success story in the industry. This partnership drives productivity, quality, and safety, enabling companies to reach new levels of excellence and secure a prominent place in a highly competitive market.

Be a witness to the ongoing industrial revolution and embark on this journey with arc welding and robots, preparing for an exciting future full of possibilities! 💪🏭🌟