Tips for Choosing the Best Industrial Robotics Solution for Different Industries

Industrial robotics has played an increasingly important role in automating industrial processes, bringing efficiency, productivity, and quality to businesses. When choosing the best industrial robotics solution for your company, it is essential to consider several important factors that align with the specific needs and requirements of your industry. Here are some tips to help you make the right choice:

1️⃣ Evaluate production requirements: Carefully analyze the production requirements of your industry. Consider factors such as production volume, speed, accuracy, type of task, and required flexibility. This will help determine the most suitable type of industrial robot for your application.

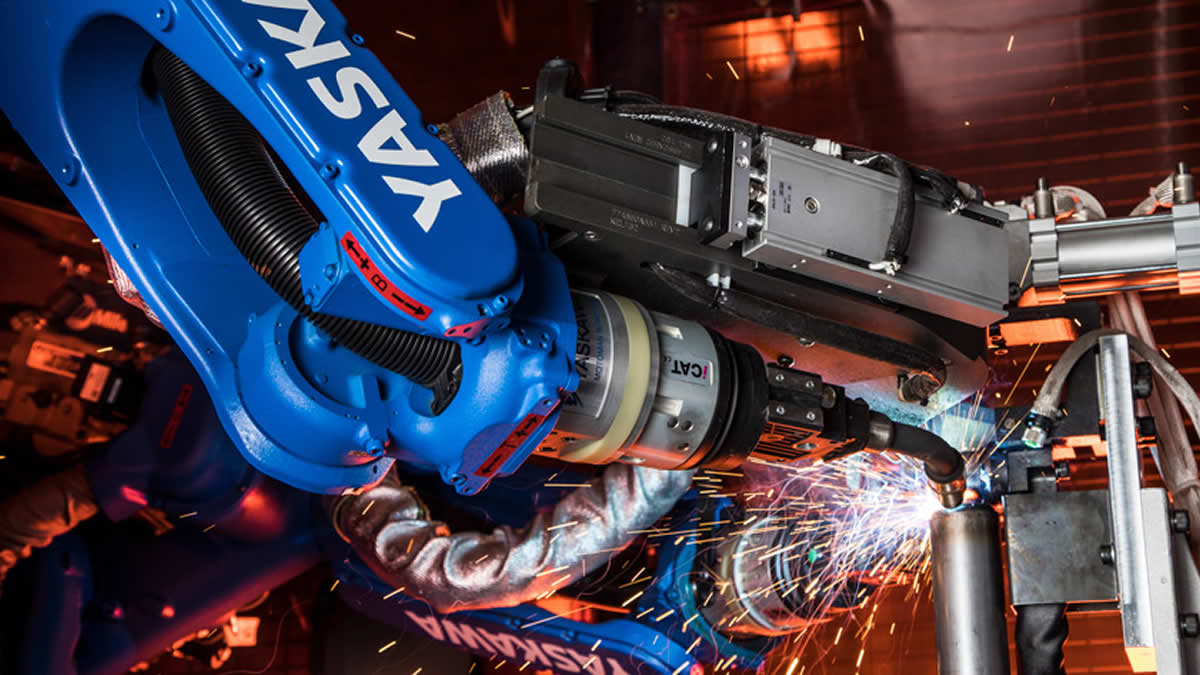

2️⃣ Choose the appropriate robot type: There are different types of industrial robots, such as manipulator robots, collaborative robots (cobots), mobile robots, and welding robots, among others. Based on the production requirements, select the type of robot that best fits your needs.

3️⃣ Consider the work environment: The work environment is a critical factor to consider when choosing an industrial robotics solution. Ensure that the robot is designed to operate safely in the conditions present in your industry, such as temperature, humidity, presence of dust, or chemicals.

4️⃣ Evaluate flexibility: Flexibility of the robot is crucial for adaptability to different tasks and products. Consider whether the robot can be easily reprogrammed to perform different activities and whether it can be integrated with other existing automation systems.

5️⃣ Think about safety: Safety is a crucial concern in industrial robotics. Make sure that the robot has adequate safety features, such as collision sensors, emergency stop systems, and speed control, to ensure the protection of operators and other employees.

6️⃣ Check ease of use: User interface and ease of programming are important factors to consider. An intuitive and user-friendly industrial robotics system can reduce training time and increase operational efficiency.

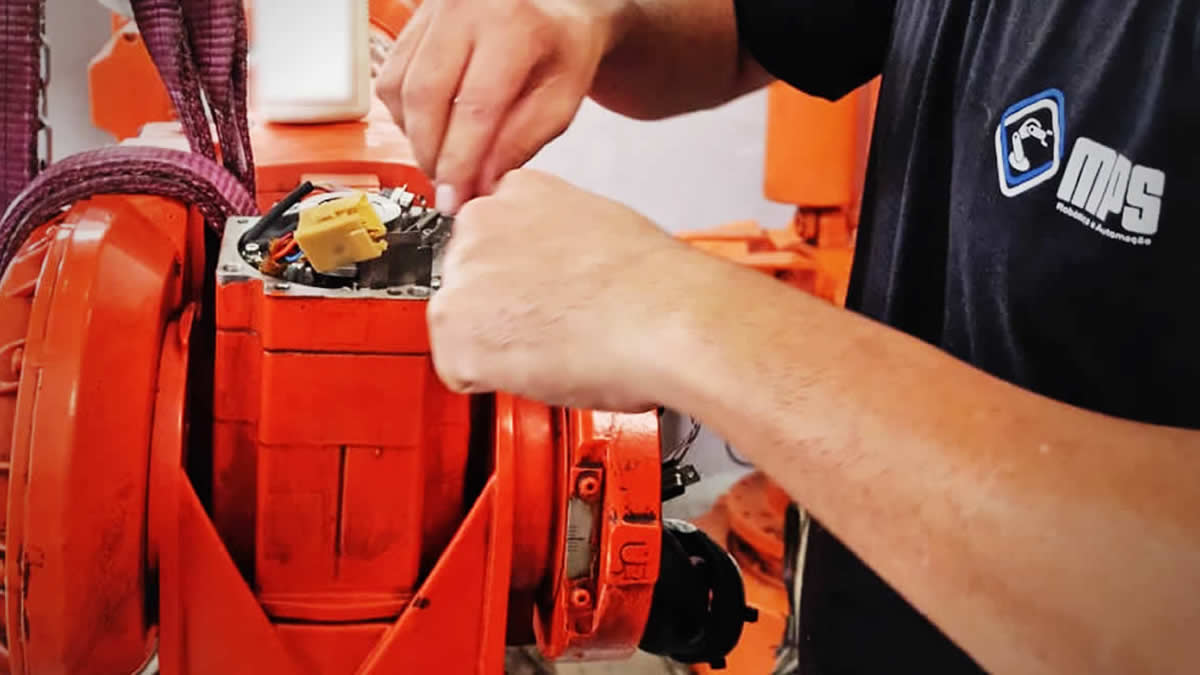

7️⃣ Consider technical support: Verify if the supplier of the industrial robotics solution offers reliable and available technical support. This can be essential for troubleshooting, providing software updates, and maintaining system performance over time.

8️⃣ Evaluate cost-effectiveness: In addition to the robot's acquisition price, take into account operational costs such as maintenance, spare parts, and energy consumption. Calculate the expected return on investment (ROI) to determine if the industrial robotics solution offers good cost-effectiveness.

Please note that each industry has its own needs and peculiarities, so it is important to consult experts in industrial robotics and robot manufacturers for more specific and personalized guidance.

🤖💡 We hope these tips help you choose the best industrial robotics solution for your industry, driving automation and the growth of your business! 💡🤖